Rapid Prototyping

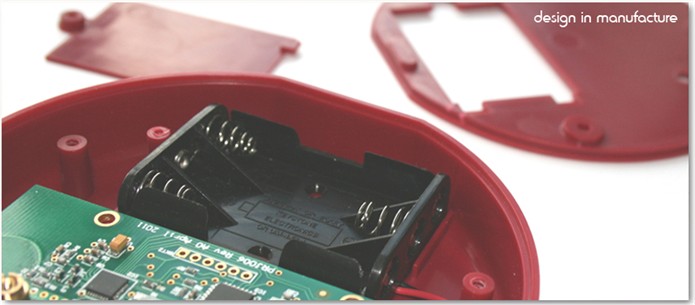

We were approached by a company producing high-tech revolutionary skiing aids for people who want to ski all day. We got involved in the development of the Mk II product, firstly offering advice on rapid prototyping material and process choice for the functional testing of the product. This initially involved theoretical mechanical testing using FEA software, creating custom materials for the process. We went on to create the functional prototypes using the Selective Laser Sintering Rapid Prototyping process to create Nylon glass filled prototypes. The design went through several iterations and functional testing carried out by Ski Mojo. We helped through to the final stage where they could move forward to injection mould tooling. At this stage, materials and tooling advice was given to ensure that the product would be robust and appropriate enough for its repetitive use. The Bill of Materials involved a range of small machined parts, we produced 2D production drawings to develop an on demand process with quality local suppliers for small batch production to keep up with the rapid SLS process.

If you would like more information on plastic component design and similar projects please do not hesitate to contact us on 0843 886 6468 or email design@p1technology.com.

© 2025 - P1 Technology. Registered Number: 05022001 | Privacy Policy | Terms and conditions | Disclaimer