Consumer Product Design

Envirofeed approached P1 Technology to develop a patented plant food maker towards manufacture. The concept for the product is to allow users to produce their own plant food by oxidising biodegradable vegetable matter within water over the course of 7 days. The project had already been through the concept development and functional testing stages.

Our role was to develop the product aesthetics and design for manufacture so that the product would attract potential investors. The key aim was to minimise costs to ensure a 50% profit margin on the product. This was achieved by sourcing two components from existing suppliers and retro fitting the bespoke elements of the design to suit. The project is currently in development with the aim to produce a final pre manufacture prototype before major investment in tooling.

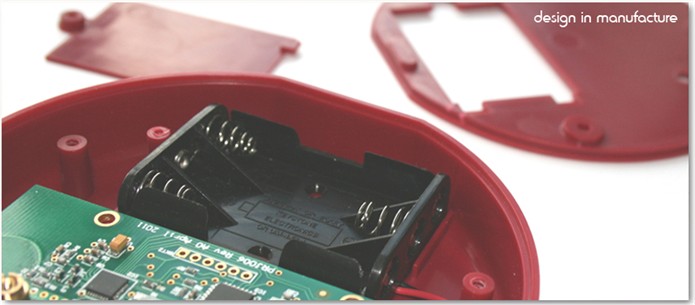

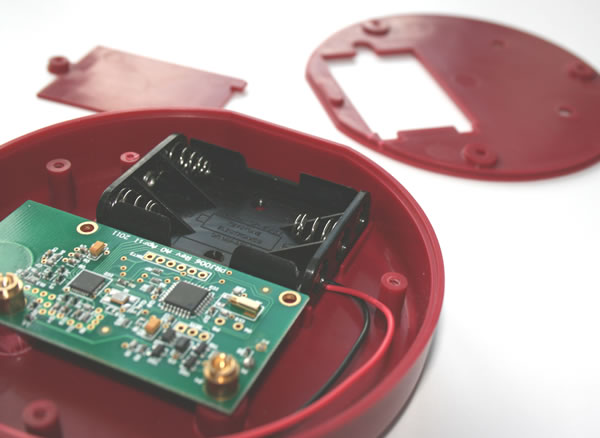

Real Time Location Technologies are a company specialising in state of the art retail communication units. P1 Technology were asked to develop a communication unit for restaurants to inform waiters of the location of the customer specific to each order. The product would be part of a large stackable batch which would only require one base power unit. The key part of the design was to ensure that each unit would all stack to allow electric current to transfer through the charge pins so that the power would be off when stacked. We also had to incorporate an area for product branding. The electronics and components were already sourced by RTLT.

Our role was to design the plastic enclosure which would accomodate all components. The product was designed for a simple open and shut tool without side movers to minimise costs. The product is currently in production.

P1 Technology were consulted by Endoclean with a request to design a cleaning instrument for medical endoscopes. The design brief was essentially to replace the variable quality of manual cleaning, with an automated measurable process which could not only increase cleaning speed but remove the possibility of human error improving a very important part of medical sanitation. We concentrated on firstly producing concepts for the mechanism to ensure that the products function was the main concern. Basic 3D CAD and prototypes were initially produced to verify the concept of automating a wire brush to oscillate whilst moving down the internal channels of the endoscope. This was produced using an asymmetrical timer switches for both forward and reverse oscillation.

As the project has progressed, we have worked in partnership with a brush manufacturer to finalise the design. Tests have been developed and conducted by our workshop staff into controlling the power and strength of the oscillations of the wire brush for up to 3 metres to increase the efficiency of the product. The project has now been granted patent and is in the process of a batch manufacture medical trial.

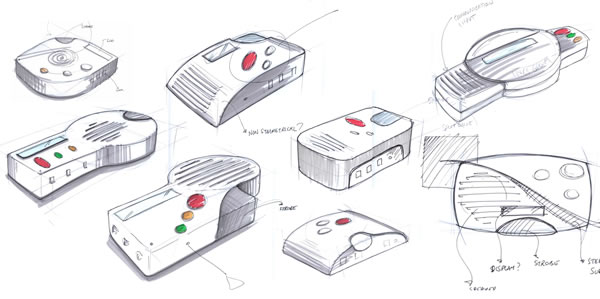

P1 Technology were asked to design concepts for a 'carephone' for the elderly with a close consideration for manufacture as part of a Manufacturing Advisory Service (MAS) . NCS group have over 18 years of experience in care phones and outlined a detailed specification for the design. Sketch concepts were produced to help guage the type of form and aesthetics with a broad range of styles to help inform the customer's vision.

This helped to define areas of the design and chosen concepts were developed in more detail (see overleaf). More concepts were then refined and modelled in Solidworks and rendered using Photoview 360.

If you would like us to examine your existing practices to develop areas of improvement for product development please do not hesitate to contact us on 0843 886 6468 or email design@p1technology.com.

© 2025 - P1 Technology. Registered Number: 05022001 | Privacy Policy | Terms and conditions | Disclaimer