Product Design and Development

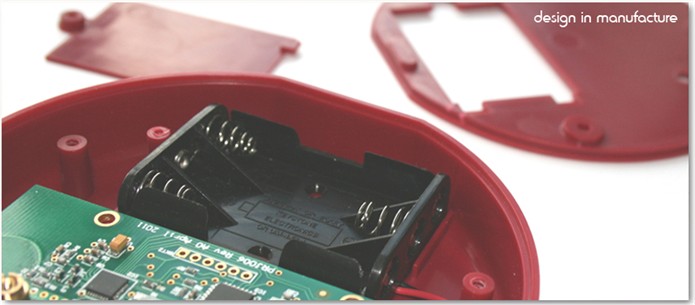

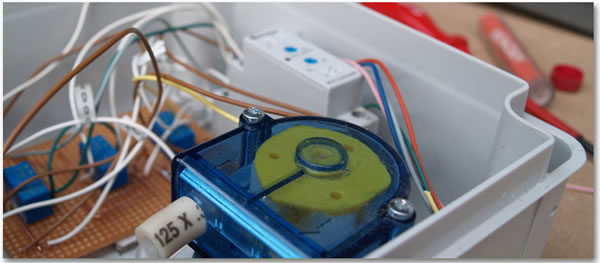

We pride ourselves in gearing development towards eventual manufacture to ensure efficient use of your time and resources. Essentially development involves stringent testing to ensure that your project will be a success. This can involve a wide range of tools depending on the client's requirements.

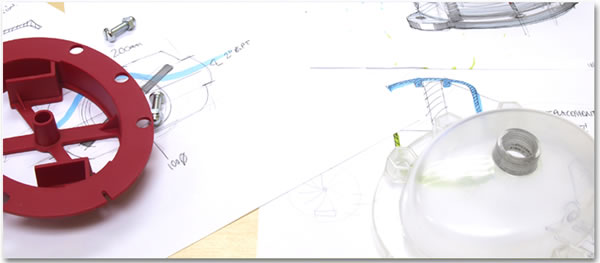

3D CAD & Design Sketches

Depending on the detail required, 3D CAD and design sketches are typically used to clearly communicate design changes for verification to clients and suppliers. Our experienced design team have strong 3D sketching skills as well as formal Solidworks 3D CAD training and are able to produce 3D CAD models to a highly advanced level; from basic sketch models to complex surfacing.

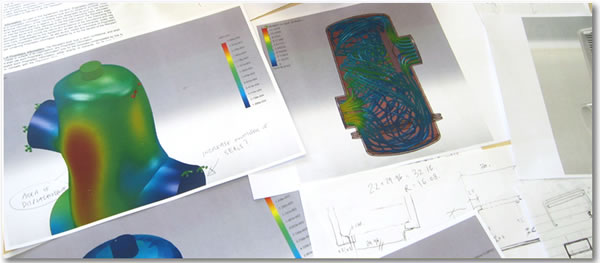

Simulation Techniques

Design verification FEA analysis software works by eliminating the need for unnecessary prototyping and accelerates the design process to find a functional solution . Whether you have an already designed product which requires analysis or you would like to use simulation techniques as part of your development process, we can help. Some of our key areas of simulation include:

COSMOS Simulation

We can help you optimise alternatives by comparing strengths, life, costs, materials and weight. Solidworks simulation includes failure prediction, drop test or impact simulation buckling or collapse prediction, heating or cooling simulation and repeated loading simulation.

Floworks Simulation

Depending on your design we can simulate liquid and gas flow in real world conditions, run "what if" scenarios, and analyse the effects of fluid flow, heat transfer, and related forces on immersed or surrounding components. Floworks simulation includes radiation heat analysis, internal flow analysis, rotation reference frame analysis, transient flow analysis and conduction/convection heat transfer analysis.

3D Scanning/ Reverse Engineering

Within your project you may require some existing design work to be replicated to suit your new design project. By using 3D scanning we are able collate point cloud data to create CAD models of a real world object to a near perfect degree of accuracy. The data can then be used to construct digital 3D models useful for a wide variety of applications within your project.

Sourcing Suppliers

We are able to source a wide variety of products with high quality at a low price. Whether you require components, parts, materials, 3D scanning, prototyping, tooling, or manufacturers we can help. Where possible we aim to use local suppliers and manufacturers to support local industries. For large scale manufacture we have an excellent working relationship with manufacturers in China, particularly with regards to injection mould tooling.

If you would like to discuss your project for us to formulate a proposal please get in touch on 0843 886 6468, email design@p1technology.com or fill in our online enquiry form. Please also take the time to look at our offers and links for available funding.

© 2025 - P1 Technology. Registered Number: 05022001 | Privacy Policy | Terms and conditions | Disclaimer